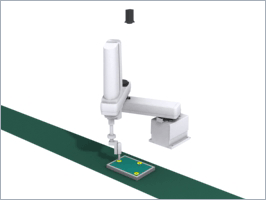

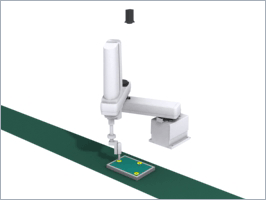

Screw tightening work using robot vision iVY system

|

The iVY system highly functionalizes screw tightening work by a SCARA robot

|

- Various conditions can be handled by adding the iVY system’s position detection function.For example, the robot can be easily incorporated in cases such as when the screw hole positions are inconsistent, the workpiece position on the conveyor is not consistent, or when multiple types of workpieces are supplied.

- The iVY system can be calibrated with simple operations. The teaching process can be reduced, so the system startup time can be shortened and labor costs can be reduced, etc.

|

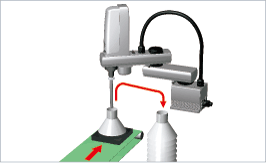

Tall work pieces conveying and stacking machine

|

Tall workpieces stacked by utilizing long Z axis.

|

- Use of SCARA can cope with the Z axis long stroke as a quasi standard.

- Advantages of use of SCARA: speed of XY axis and space

saving installation.

|

Finished product inspection, touch-panel type evaluation machine

|

Finished product function test.

Developed software evaluation.

Push button type quality check.

|

- Supports a variety of systems in a product lineup that is top class in its field with arm lengths from 120mm to 1200mm.

- Space saving.

- Using SCARA, judgment is made through image processing by pushing each button.

|

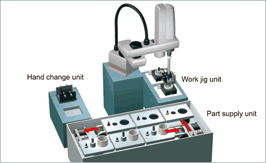

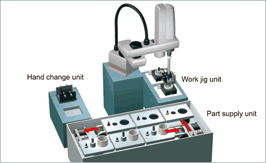

Assembly cell (independent cell)

|

Base machine of independent type assembly cell.

|

- Optimum for multi type variable quantity production.

- Setting up reception places forms a construction of multiple number of cells.

|

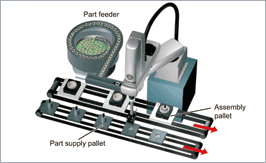

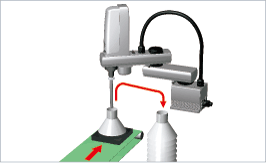

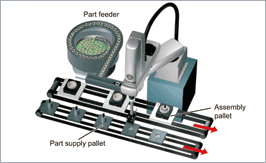

Assembly cell (line cell)

|

Base machine of line type assembly cell.

|

- Utilization of advantages of SCARA with a wide operation range.

- Form a line to any length by coupling these cells together.

|

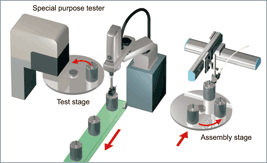

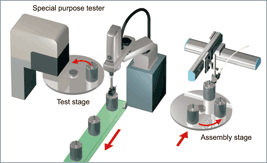

Assembly cell (Handling unit for special purpose tester)

|

When placed between 2 turn tables, handling of both tables is possible.

|

- Utilization of advantages of SCARA which has a wide operation range.

|